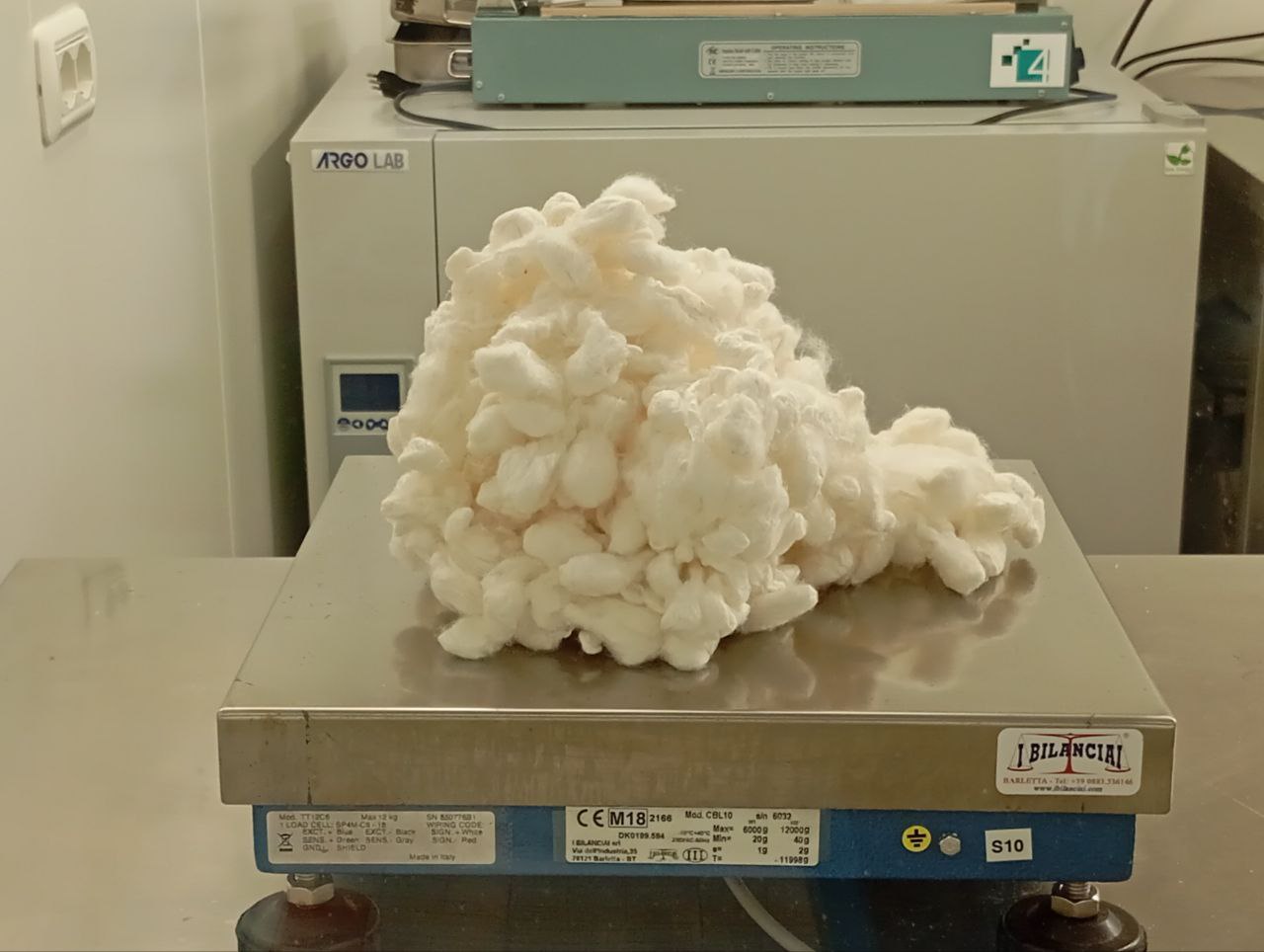

Silk fibroin extracted from the cocoons of Bombyx mori is a fibrous glycoprotein whose molecular architecture makes it, not by chance but by evolutionary necessity, one of the optically clearest biological polymers found in nature. The heavy chain (Hc), with a molecular weight of approximately 350 kDa, is linked by a disulfide bond to the light chain (Lc) of approximately 25 kDa, forming the (H-L) complex; this complex interacts with the 27 kDa glycoprotein P25 in a 6:6:1 molar ratio. It is precisely the structural hierarchy emerging from these elements — β-sheet nanocrystals embedded in a semi-amorphous matrix of random coil and α-helices — that determines the optical properties.

In regenerated thin-film fibroin, optical transmittance exceeds 90% across the entire range from visible to near-infrared (300–2000 nm), a figure rigorously measured by UV-Vis-NIR spectroscopy and confirmed by recent photonics studies.

The refractive index (RI) of fibroin has been precisely characterised through broadband ellipsometry (250–1750 nm): at 500 nm, the RI of regenerated B. mori fibroin sits at around 1.54–1.55, with values increasing in more crystalline structures up to 1.566 ± 0.001 for fibroin extracted directly from the native silk gland. The variability of the refractive index as a function of β-sheet crystallinity is a fundamental property: treatment with water vapour (water annealing) or methanol induces the conformational transition from the Silk I structure (α-helices, random coil) to the Silk II structure (β-sheet), increasing the material density and consequently its refractive index in a programmable and controlled manner. This structural tunability has no equivalent in conventional transparent synthetic polymers such as Parylene-C or PDMS.

Scattering losses in planar fibroin waveguides have been measured using the fiber probe technique at 632.8 nm and amount to approximately 0.22 dB·cm?¹, a value that makes fibroin competitive with other biocompatible optical materials for implantable photonics applications. The optical loss parameter is critical in any implantable display architecture: materials with excessive losses would render any light-guiding mechanism inefficient and compromise the definition of the image or luminous signal.

The photomechanics of fibroin: photoelasticity and stability in physiological environments

A technical aspect rarely discussed in the context of biomedical displays is the photoelastic behaviour of the substrate — that is, how mechanical deformations induced by tissue contact modify the optical properties of the material. This interdependence, known as the photomechanical effect or photoelasticity, is particularly relevant for devices in contact with the skin or cortical surfaces, where continuous mechanical forces — pressure, stretching, haemodynamic pulsations — induce local stress on the substrate.

Studies conducted using Whispering Gallery Mode (WGM) resonators and Brillouin light scattering (BLS) spectroscopy on fibroin have demonstrated that the formation of β-sheets in the Silk II structure simultaneously modifies the optical and mechanical properties of the protein, dominating its photoelasticity. The Pockels constants of the two structural states (amorphous Silk I and semi-crystalline Silk II) were extracted from the intensity of the Brillouin peaks, while the Young's modulus and Poisson's ratio of both phases were measured at zero deformation in non-contact mode. The practical result is that the degree of crystallinity determines not only the static transparency of the film, but also its optical response under mechanical load — an essential design factor for displays subjected to cyclic deformations.

Stability in aqueous environments is the other critical variable. Untreated regenerated fibroin dissolves in water, making its direct use in humid physiological environments impossible. The pre-stretching treatment of films, recently developed for bioelectronic applications, allows the induction of controlled molecular orientation and anisotropic crystallisation that markedly increase aqueous stability without resorting to potentially cytotoxic chemical cross-linking. OC (open-circuit) devices based on this approach have demonstrated an SNR above 20 dB in in vivo EMG acquisitions on murine models for over seven consecutive days, confirming the durability of the material under real physiological conditions.

E-ink displays on composite fibroin substrates

Realising a functional display on a protein substrate requires a hierarchy of engineering solutions ranging from film formulation to the selection of the visual emission mechanism. The intrinsic limitations of pure fibroin — mechanical brittleness, poor moisture resistance, and chemical instability in acidic or basic environments — have been addressed through mesoscopic doping strategies that alter the secondary structure of the protein without compromising its biocompatibility.

The most studied system for display applications involves co-processing of regenerated fibroin and polyurethane (PU) with the addition of isopropanol (IPA) as a plasticiser. The chain cross-linking effect induced by PU on the secondary architecture of fibroin increases the β-sheet content, translating into greater mechanical robustness and flexural resistance (over 1000 bending cycles documented), thermal resistance up to 373 K, and tolerance to pH 3–11 — conditions that span well beyond the physiological range. In parallel, the composite film retains the biocompatibility and enzymatic degradability of the protein precursor, properties validated by FDA approval for biomedical applications of fibroin.

Conductive layers of AgNWs (silver nanowires) are deposited on this composite substrate through controlled coating technology. Silver nanowires, with diameters in the tens of nanometres and lengths in the micrometre range, form three-dimensional percolative networks that ensure electrical conductivity while maintaining high optical transmittance of the substrate — a combination impossible to achieve with continuous metallic films. The strategy of embedding the nanowires within the film during the casting of the fibroin solution increases interfacial adhesion between the two materials, reducing contact resistance and improving the mechanical stability of the electrode during bending.

The display technology chosen for these architectures is not LED or OLED, but e-ink (electronic ink). The reason is both technical and medical: spontaneous emission displays require continuous currents that can generate localised heat and interfere with surrounding tissues; e-ink, by contrast, consumes energy only during the state transition — the bistable display — and maintains the image without continuous power, drastically reducing thermal dissipation and the risk of tissue damage. For cutaneous applications and those close to the body surface, where even temperature variations of 1–2 °C can alter the local biological response, this factor carries decisive weight in the choice of display paradigm.

Optical waveguides in fibroin for subcutaneous imaging and photodynamic stimulation

Fibroin is not merely a passive substrate for planar electrodes. Its function as an optical waveguide opens up substantially different technical possibilities: the confinement and transmission of light through opaque biological tissues for imaging, diagnostics, and implantable photodynamic therapy.

The planar waveguide structure in fibroin exploits the refractive index contrast between the protein core (n ≈ 1.55) and the biological cladding (n ≈ 1.38–1.45 for soft tissues), analogously to inorganic dielectric systems, but with the advantage of a mechanically conformal and biochemically compatible interface with the tissue. Guiding has been experimentally verified at wavelengths of 473, 632.8, 964, 1311 and 1552 nm, covering a range from visible to near-infrared, relevant both for visualisation and for the first and second biological optical windows (650–950 nm and 1000–1350 nm respectively), where tissues exhibit the lowest absorption.

A technically sophisticated instance of this application is the so-called Silk-Optrode: an optoelectronic probe that integrates fibroin waveguiding with neural recording functionality and antimicrobial properties. The concept is particularly relevant to infections associated with chronic implantable devices, one of the main clinical limitations of conventional neural probes. Integrating optical, electrical, and biochemical function into a single thin, flexible protein structure represents a radically different architectural paradigm compared to silicon- or noble-metal-based systems.

For the fabrication of fibroin microlenses — elements that can be integrated into 2D arrays for focusing the light signal in implantable imaging systems — the programmable wettability of the protein solution on PDMS-patterned substrates is exploited. Fibroin in solution, deposited onto a micropatterned master, assumes a consistent radius of curvature across the entire area of each individual optical element thanks to the identical wetting area per pattern unit, producing a microlens array with highly uniform focal length. This self-assembly approach is an example of how the aqueous processability of fibroin — without toxic organic solvents — becomes a direct technological advantage in the fabrication of precision micro-optics.